| Business Type | Manufacturer, Exporter |

| Power Supply | Electric |

| Brand Name | UGP |

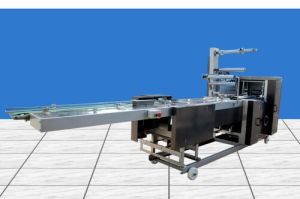

| Packaging Type | Horizontal Form Fill Seal Machine |

| Click to view more | |

Product Details

Sealing Type

Pillow Pack/pouch Pack

Machine Type

Automatic

Usage

Industrial

Capacity

UP TO 300PPM

Product Code

UGP7250FS

Delivery Time

45 Days

Details

- Detergent Bar Packaging Machine has been designed to pack detergent cakes/ Laundry cake in single wrap of wrapping paper

- Machine has been designed to handle heat sealable wrapper, laminates and Poly coated wrapping material

- The machine is built from high precision components having the desired metallurgical and heat treatment characteristics, resulting in lower wear and tear, high life and less maintenance

Working Principle

- The soap cakes are fed onto a continuous motion In-feed Conveyor

- The In-feed pushers take the soap cakes to the wrapping feed station

- With the help of pulling rollers, the reel fed wrapper is positioned between the cakes and tumble box

- The wrapper is cut to the required length as the in-feed pushers push the soap along with the cut wrapper into the turret

- Spring-loaded end blocks retain the product in position

- The turret box then indexes by 180 degrees and resulting in top folding

- The next incoming cake pushes the previously packed cake forward which is further pushed into the sealing zone

Feature

- Machine suitable for detergent bar/laundry bar/oil cake/Toilet soap

- Heavy duty cast structure

- Machine weight: Approx. 1600 Kgs

- Speed up to 300 PPM depending upon the product dimensions, laminate quality and feeding of soap

- Directly linkable to bar cutting machine through conveyor for automatic feeding of bars

- Fixed/Adjustable size turret assembly

- Designed to handle soft bar

- Soap moves on belts with pusher to avoid any scratch mark

- Double spool arrangement for wrapper to save change over time of paper roll to increase the uptime of machine

- No soap and no wrapper interlock through PLC

- AC variable speed drive unit

- Double chain for overhead infeed conveyor

- Double chain for overhead discharge conveyor

- Speed of machine directly proportional to soap feeding

- Stop-start mechanism with Geneva Drive for auto feeder belt conveyor

- Collator unit for easy collection of packed bars

- Two sided heaters and cooling unit provide better sealability

- Double corrugation rollers

- Different cut length for paper stiffener lengths can be made at a cut off unit quickly.

- Separate temperature controller for topside heaters and rear heater

- Infeed queue pressure release mechanism while transferring the soap from infeed belt conveyor to prevent dent marks

- Centralized lubrication system

- Print control system with worm and worm wheel mechanism

- Cooling unit for electrical panel

- PID temperature controllers

- Wrapper : Paper / Poly / Hot Melt Lamination Max Dia 450mm

- Core ID 70mm

- Stiffener: Card paper/poly laminated

Looking for "UGP-7250FS Fully Automatic Multiple Axis PLC Interface High Speed 250PPM" ?

Piece

Explore More Products